Community water systems big and small are not just in charge of dispensing the water we cook with, bathe with, and drink, but also treat it so that its quality is up to snuff for human consumption. While some recent federal funding is focused on tracking and reducing the amount of PFAS and other emerging contaminants in our water systems, another significant slice is used to ensure the water in our homes is crisp and clean.

The structural challenges water and wastewater treatment facilities face are the same as those faced by community water systems: a lack of funding to replace aging infrastructure. While the average treatment facility lasts 40 to 50 years, individual components require replacement every ten to fifteen years. The EPA’s 7th Drinking Water Infrastructure Needs Survey and Assessment found that treatment systems nationwide will require $106.4 billion in the next 20 years to maintain quality, never mind the $420.8 billion required for distribution and transmission systems or the $24.9 billion required for water source development.

The Infrastructure Investment and Jobs Act (IIJA) does include three competitive programs — the Connection to Publicly Owned Treatment Works, Small and Medium Publicly Owned Treatment Works Circuit Rider Program, and the Small Publicly Owned Treatment Works Efficiency Grant Program. The first and second of these programs are funded at $40 million and $10 million respectively for fiscal years 2022-2026, a drop of funding in comparison to the ocean of need. As a result, much of the necessary infrastructure development work will have to be funded by the Drinking or Clean Water State Revolving Funds.

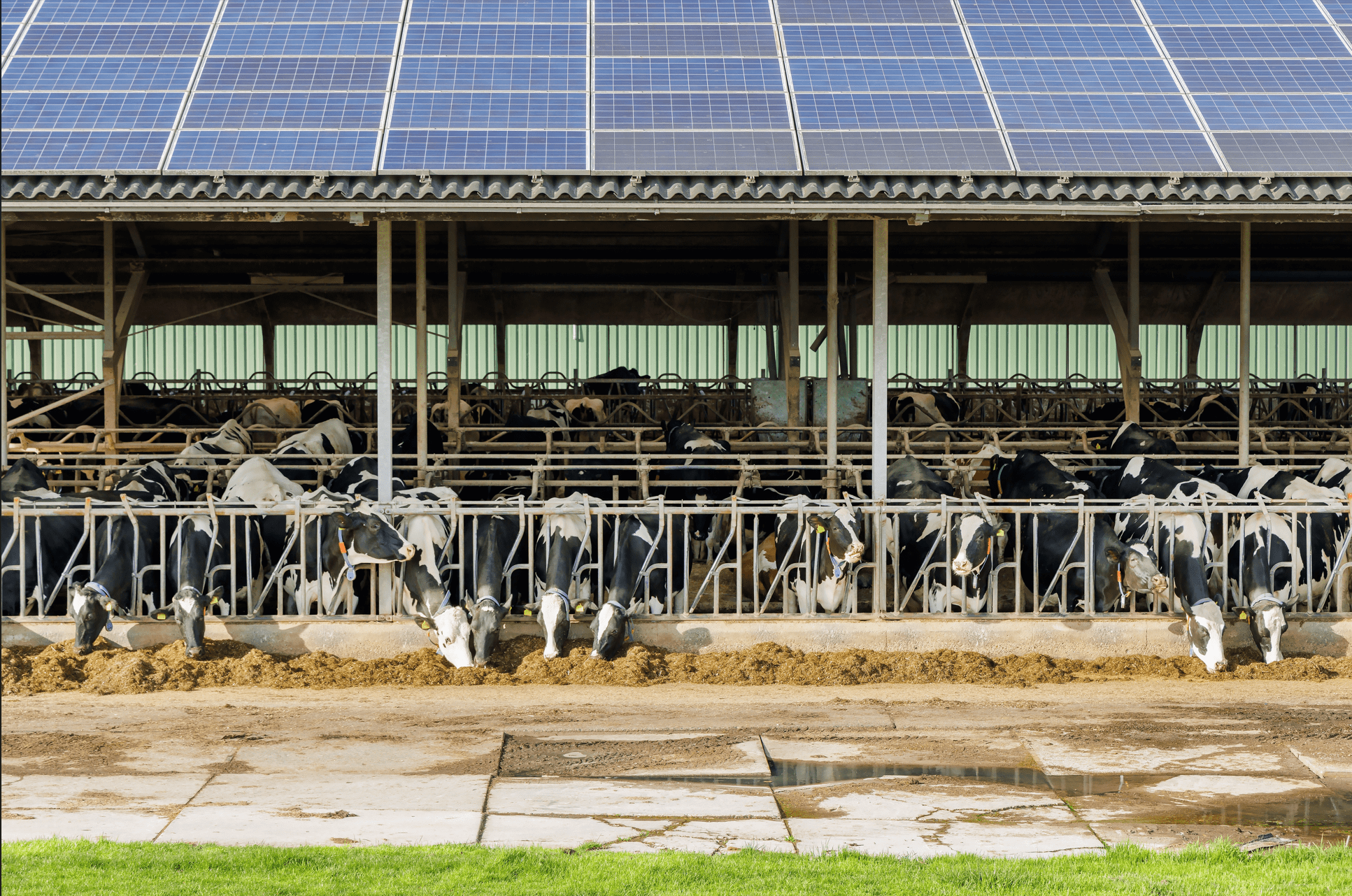

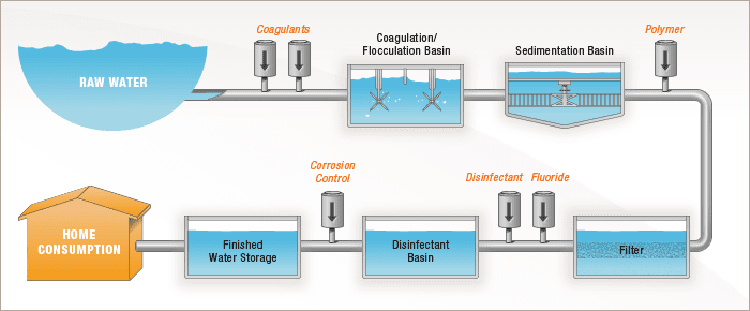

Community water systems pull in water from a local source such as a reservoir or lake, where the water that had previously been sitting in nature then undergoes treatment before being transmitted to buildings. Water utilities are responsible for the maintenance of water treatment facilities, which have many sections for each segment of the treatment process (Figure 1).

Figure 1: Water Treatment Process

Source: Denver Water

Raw or untreated water is pulled into the treatment facility, where coagulants are added to produce clumped masses of small waste particles like sand and dirt that sit in uncleaned water (flocs). In a large basin, the water is mixed to spur this clumping before being piped to a sedimentation basin. There, the water sits so that debris can settle at the bottom of the basin. Alternatively, some water treatment plants utilize a dissolved air flotation tank, where bubbles of air push the flocs to the basin’s surface, where a sweeper arm collects the sludgy waste. That sludge is separated and trashed or reused as fertilizer.

At this juncture, water may appear clear but will still contain plentiful contaminants that may threaten human health. Layers of coarse, medium-textured, and fine stacked sand form the first pass at filtration, which the water flows through so that smaller particles can be removed. Then, water is also filtered by a basin with activated carbon — the same filtering system used in products like Brita. Other filtering systems are in development and are rising in popularity, such as reverse osmosis and nanofiltration water treatments, which are currently more frequently deployed for water recycling.

Finally, the water arrives to be disinfected. In the United States, most water treatment facilities utilize chlorination, or the addition of chlorine-based compounds that eliminate microorganisms. Interestingly, chlorination is a residual process, meaning that if treated water encounters other microorganisms or contaminants down the line, it will remain safe for consumption. Less common disinfection processes include the addition of ozone or shining ultraviolet light into the water.

Now this water is ready to be used. The water is pushed into municipal mains before ending at service lines leading to our faucets. Positive pressure is maintained throughout these piping systems so that water in the earth will not seep into joints or any cracks in the distribution system. Most lead contamination of water occurs during this distribution phase — read more about the extent of lead service line existence in our water systems in this Spotlight Story.

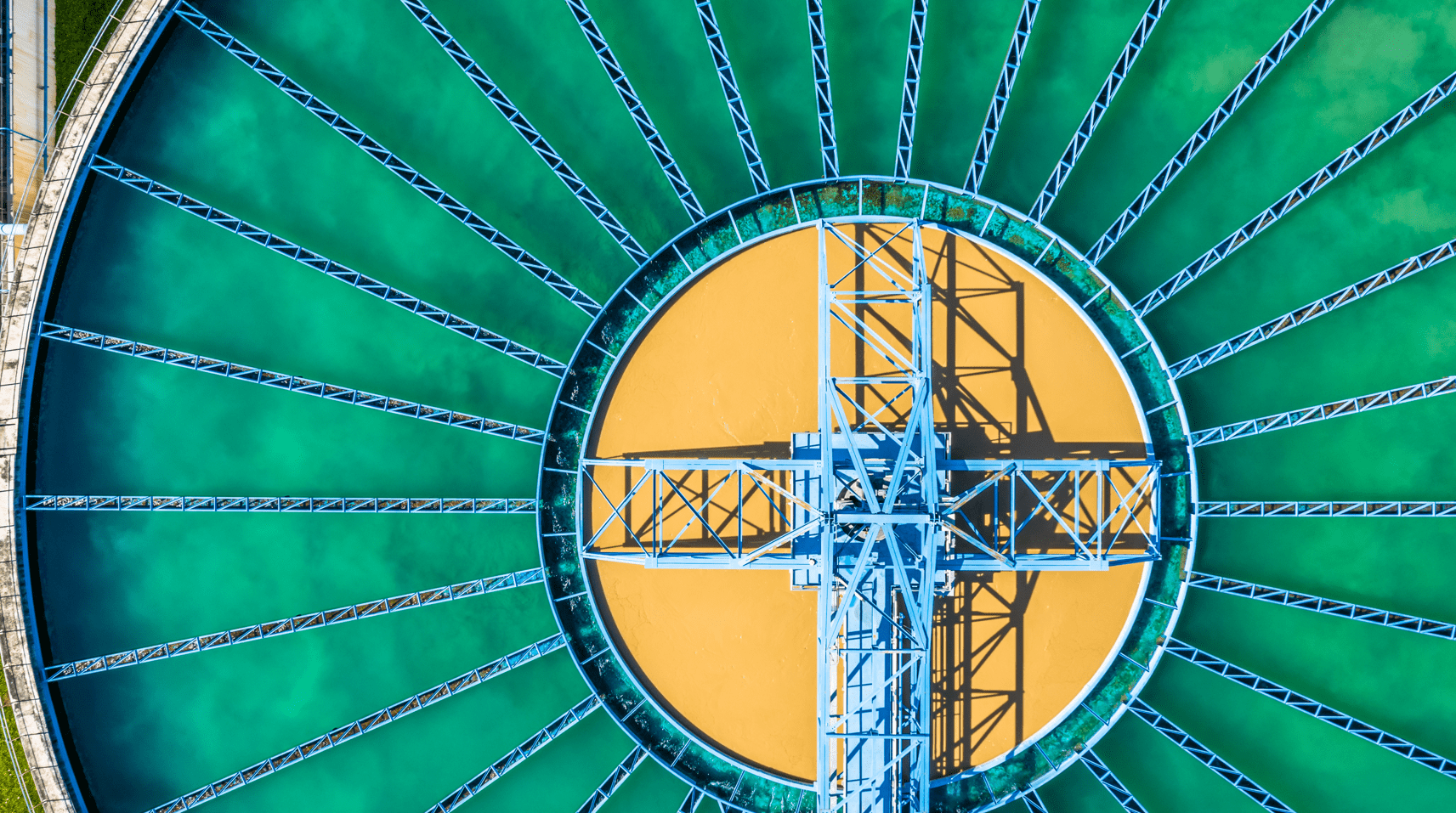

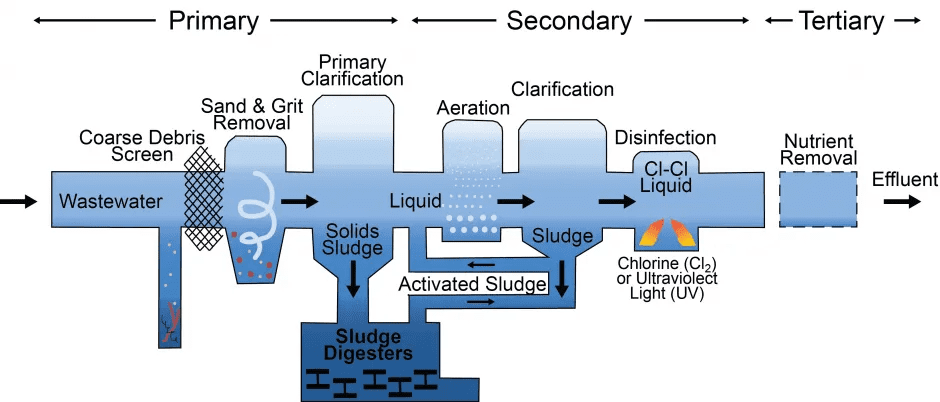

The wastewater treatment process occurring in the about 15,000 plants nationwide is similar to that of water treatment (Figure 2). Wastewater is carried from buildings’ service lines through municipal mains to wastewater treatment facilities. There, debris is removed by bar screens at the plant’s inlet before sewage is spun through a grit chamber, where large particles are removed.

Figure 2: Wastewater Treatment Process

Source: University of Michigan Center for Sustainable Systems

Next, sewage undergoes two phrases of clarification, with an aeration session sandwiched in between. Clarification basins are akin to sedimentation basins in the water treatment process, as they are where water sits so that heavier solids can settle into a sludge. The cleaner effluent up to flows over weirs into an aeration basin, to degrade its biological contents. Activated sludge full of bacteria happy to help break down our sewage is mixed into the aeration chamber via aerobic digestion. The effluent then undergoes its second clarification before being disinfected.

Post disinfection, this water is technically safe to drink. However, almost all American treatment facilities discharge the effluent into a local body of water. Some water systems, particularly those that serve regions that frequently suffer drought like the Orange County Water District, recycle this water into their drinking water systems.

In 2015, the average American used 82 gallons of water a day. All of that volume must be treated, whether it’s going into or out of a home. To keep pace with demand, our water and wastewater treatment systems need upgrades, and IIJA provides a helpful boost in funding to that end.